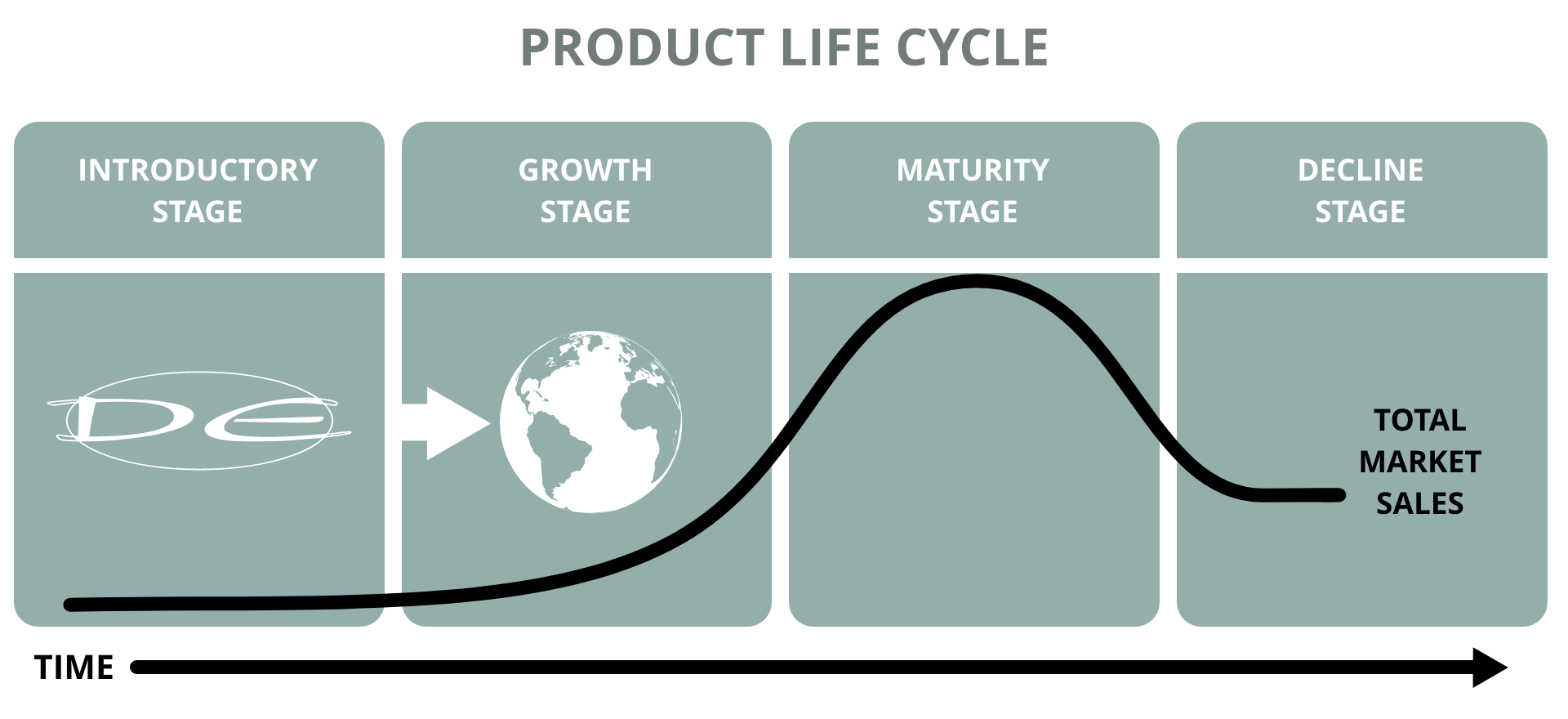

As product life cycles continue to get shorter, the need for new product innovation is relentless. If you miss opportunities to bring innovative solutions to market, your company can quickly become irrelevant. Innovation is no longer an option for growth, but a requirement for survival. And sadly, studies now suggest nearly half of the resources companies devote to the development of new products are spent on products that ultimately fail.

Deaton Engineering can help you develop a strategic plan for product and technology investment decisions based on your needs. We follow a phase-based approach to product development and innovation that includes defining user requirements, design conceptualization, development, prototyping, testing, and manufacturing preparation. We strive to help you integrate current technologies into new products, achieve superior ROI, accelerate time to market, and create a positive business impact.

At the onset of a project, Deaton Engineering works with you to carefully define the goals, user requirements, and functional specifications. We examine how the product will be used, the quantities needed, how and where the product will be manufactured, and which certifications and classifications are required.

After the product is defined, material options, manufacturing techniques, and locations are evaluated. We assess how the product can be designed within a specified budget and manufactured at a target price.

Our unique process of concurrent, multidisciplinary innovation is tailored to meet your design and manufacturing development needs. Off-the-shelf components are integrated when appropriate in order to optimize cost and efficiency. When necessary, we also employ high-end tools such as Finite Element Analysis and parametric modeling to optimize the design.

We strive to help you integrate current technologies into new products, achieve superior ROI, accelerate time to market, and create a positive business impact. Our custom equipment is designed to be easy to install, operate, and maintain with minimal engineering support. Our goal is to lower your cost of ownership by minimizing training, operator intervention, downtime, and revalidation.

Deaton Engineering provides comprehensive product development services, including:

Deaton Engineering collaborates with both startups and established companies in Texas to:

Yes, Deaton Engineering ensures that all products comply with relevant federal and Texas state regulations, facilitating smooth product launches within the state. Deaton provides engineering, design, automation, and validation services across Texas, including in Austin, Dallas, Fort Worth, Waco, Houston, and San Antonio.

Businesses can contact Deaton Engineering here or visit their Georgetown, Texas headquarters, a suburb of Austin, to discuss product development needs. Deaton provides engineering, design, automation, and validation services across Texas, including in Austin, Dallas, Fort Worth, Waco, Houston, and San Antonio.