To successfully deploy new products, you have to move quickly to get an edge in the market. And while product life cycles get ever shorter, the cost of warranty and service is on the rise. The traditional design-prototype-test approach to new product development can be slow and inefficient when problems are encountered.

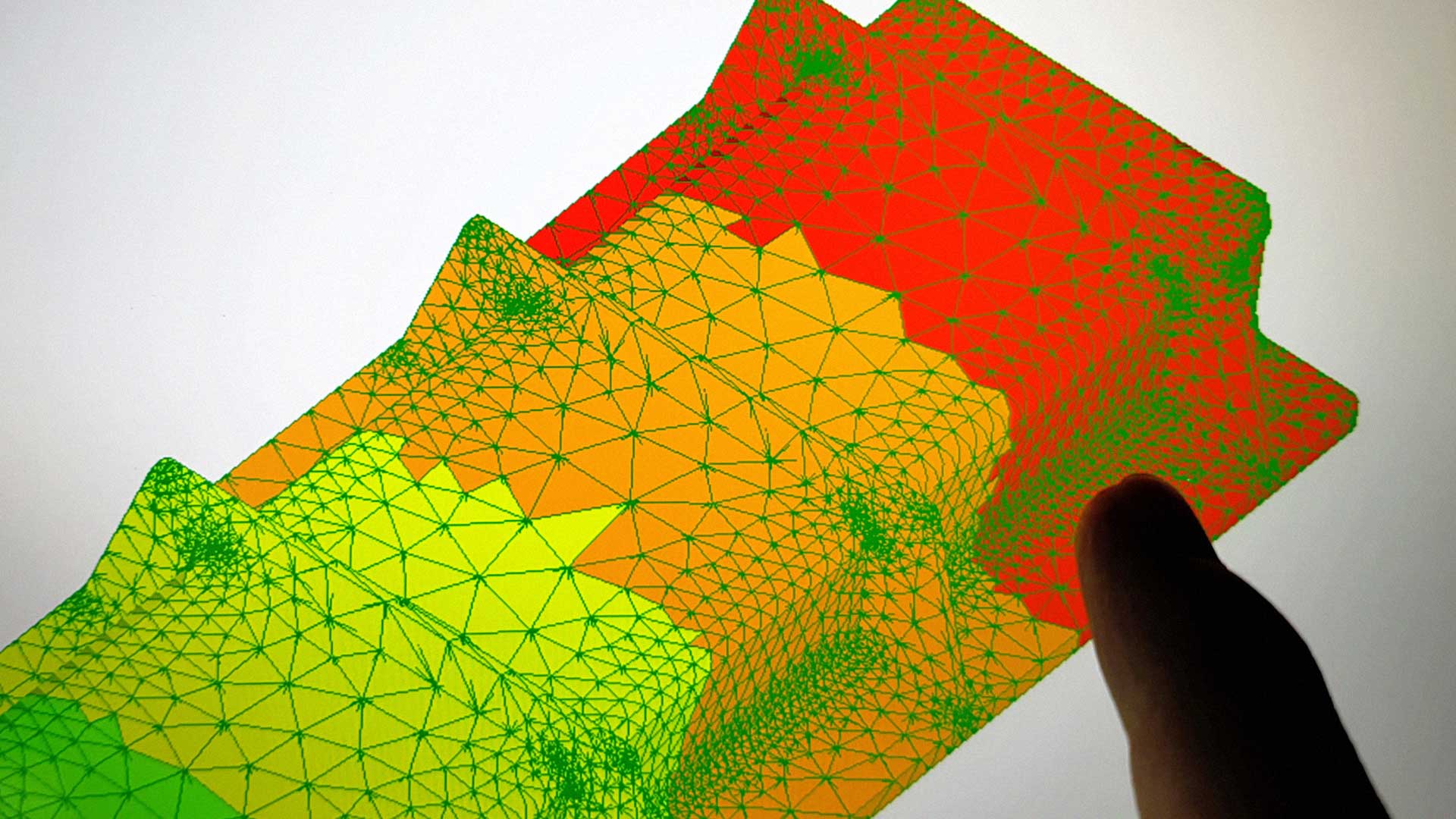

Deaton Engineering uses Finite Element Analysis (FEA) to accurately model products and processes. Our techniques can measure performance, reliability, wear points and predict failures long before you commit to tooling or start to build. We are adept at helping companies improve profitability by dramatically reducing development time, rework and quality issues. Our approach will help you speed up the design process through rapid optimization.

Our goal is to reduce product development costs and improve quality. FEA helps solve design challenges without arduous manual iterations or prototyping.

Experienced mechanical engineers verify all FEA findings against empirical test data, simplified models, and classical calculations to ensure accuracy. 3-D modeling is also used to validate designs.

Utilize FEA to reduce product development costs, limit liability risk, reduce time to market, and support FDA 510k filings. Identify and analyze worst-case implantable device size for use in mechanical testing. Verify radial force, anchoring, dynamic compliance, and fatigue loading conditions.

We strive to help you integrate current technologies into new products, achieve superior ROI, accelerate time to market, and create a positive business impact. Our custom equipment is designed to be easy to install, operate, and maintain with minimal engineering support. Our goal is to lower your cost of ownership by minimizing training, operator intervention, downtime, and revalidation.