Manufacturing is not what it used to be. Competition in today’s global marketplace is intense, and domestic manufacturers must work harder than ever to succeed. Compounding these challenges are customers and retailers that are savvier than ever, demanding lower prices and faster delivery times.

To be successful, manufacturers must seek new strategies for controlling operating costs. While some may abandon domestic facilities and ship their operations overseas, this approach is often fraught with challenges. An alternative approach is to improve the efficiency of your current manufacturing process — right here, right now — with automation.

Deaton Engineering helps North American manufacturing companies dramatically improve the quality and efficiency of their operation through the use of automation, robotics, and other efficiency measures that are often more cost-effective and profitable than off-shoring. Through automation, we can optimize your capital and labor resources in production, inventory management, quality control, and warehousing. Not only will you become more efficient and cost competitive, but you’ll also maintain tighter control of the operation than with manufacturing overseas.

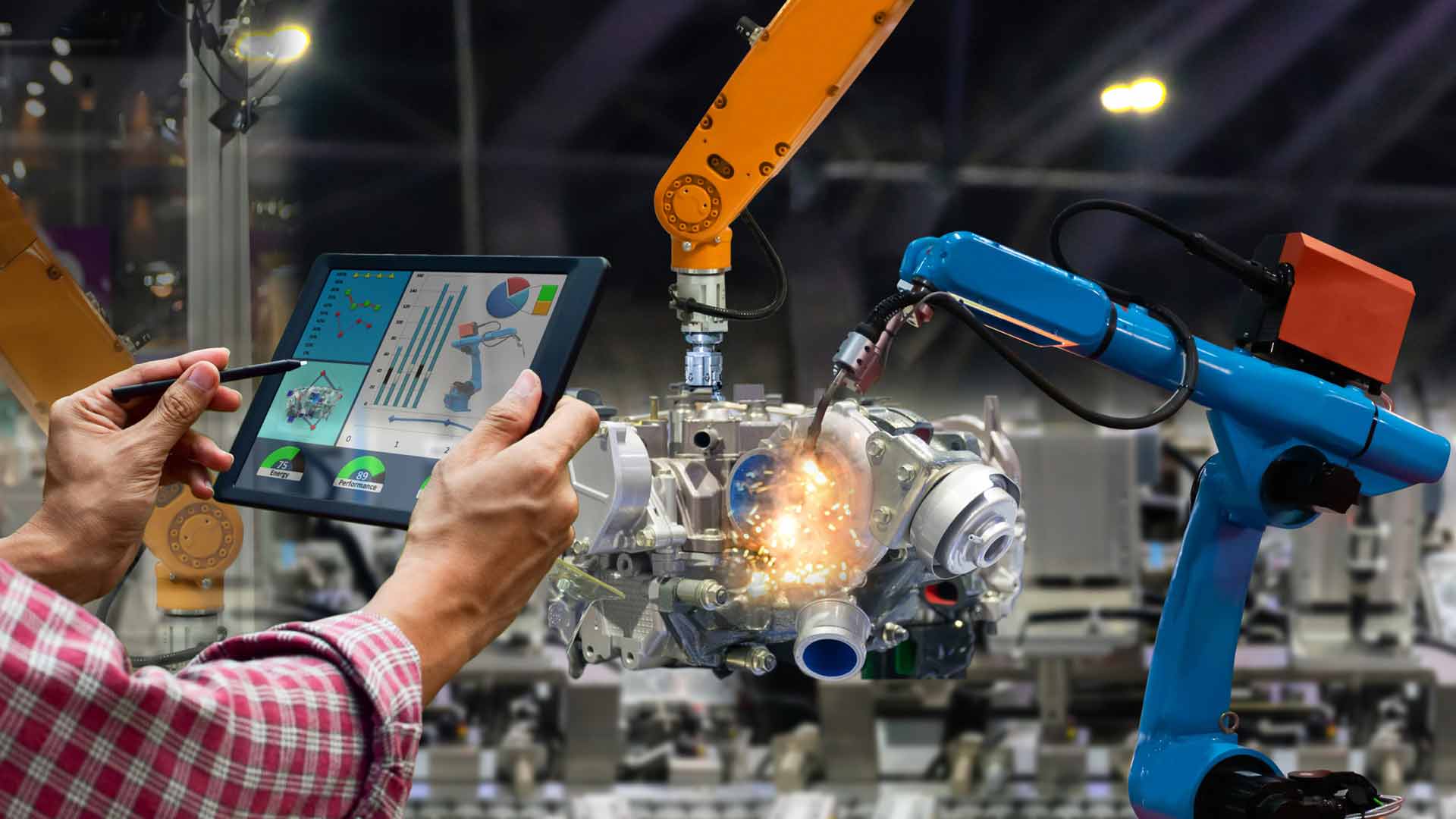

Deaton Engineering designs fully automated control systems that incorporate industrial robots, vision systems, custom hardware, and quality control measurement techniques.

Deaton Engineering works with numerous robot manufacturers to implement automation systems encompassing all forms of robotics including: pick and place, Cartesian, SCARA, and 4 and 6 axis robots. Deaton Engineering integrates robots ideal for automating applications such as palletizing, machine tending, material handling, packaging, cutting, material removal, and welding. We can also provide testing services for existing robotic systems.

Bridging the automation-to-enterprise gap is about leveraging manufacturing data in enterprise decisions. Deaton Engineering designs semi- and fully- automated test devices for manufacturing lines. We team with you to integrate quality control systems designed to continuously improve product quality and increase efficiency.

We strive to help you integrate current technologies into new products, achieve superior ROI, accelerate time to market, and create a positive business impact. Our custom equipment is designed to be easy to install, operate, and maintain with minimal engineering support. Our goal is to lower your cost of ownership by minimizing training, operator intervention, downtime, and revalidation.