Clean Energy Made Safer:

Deaton Designs & Builds Ultrasonic Deterrents to Prevent Bat Fatalities at Wind Farms.

The Client: Bat Conservation International, Inc.

Bat Conservation International, Inc. is on a mission to conserve bats and their ecosystems across the world. BCI combines science-based conservation efforts, research, and education to ensure that the bat population is protected now and into the future. Founded in 1982 and based in Austin, TX, BCI boasts a staff of more than 30 biologists, educators and administrators, and is supported by members in some 60 countries.

As wind energy continues to grow as an alternative energy source, the toll of wind turbines on wildlife – particularly bats and birds – is a major concern for BCI. BCI created the Bats and Wind Energy Cooperative (BWEC) along with the U.S. Fish & Wildlife Service, the American Wind Energy Association (AWEA), and the National Renewable Energy Laboratory (NREL, under the direction of the U.S. Department of Energy). BWEC’s focus is to reduce, to the greatest extent practicable, the number of bat fatalities at wind-energy sites.

The Challenge: Design and Build Ultrasonic Deterrents

In 2009, BCI began working with Deaton Engineering (DEI) to complete the design and build of an ultrasonic deterrent system to be mounted to a wind turbine with little or no modifications to the turbine. BCI had performed tests with early-generation devices at ground level in the years prior, but did not have a system that could be manufactured and deployed directly on to wind turbines. The deterrent system needed to withstand the harsh environment present at wind-energy sites, while providing adequate coverage of the turbine with sufficient amplitude of ultrasonic output over a frequency range of up to 100 kHz.

The Solution: Wind Turbine-Installed Bat Deterrent System

DEI developed an algorithm to generate white noise over a frequency range of 10 kHz to 100 kHz, and implemented the algorithm with a microcontroller-based PCB design and a custom amplifier circuit. DEI designed enclosures that held up to harsh weather while still maintaining the pressure equalization required to allow the ultrasonic transducers to function. Each enclosure housed 16 ultrasonic transducers.

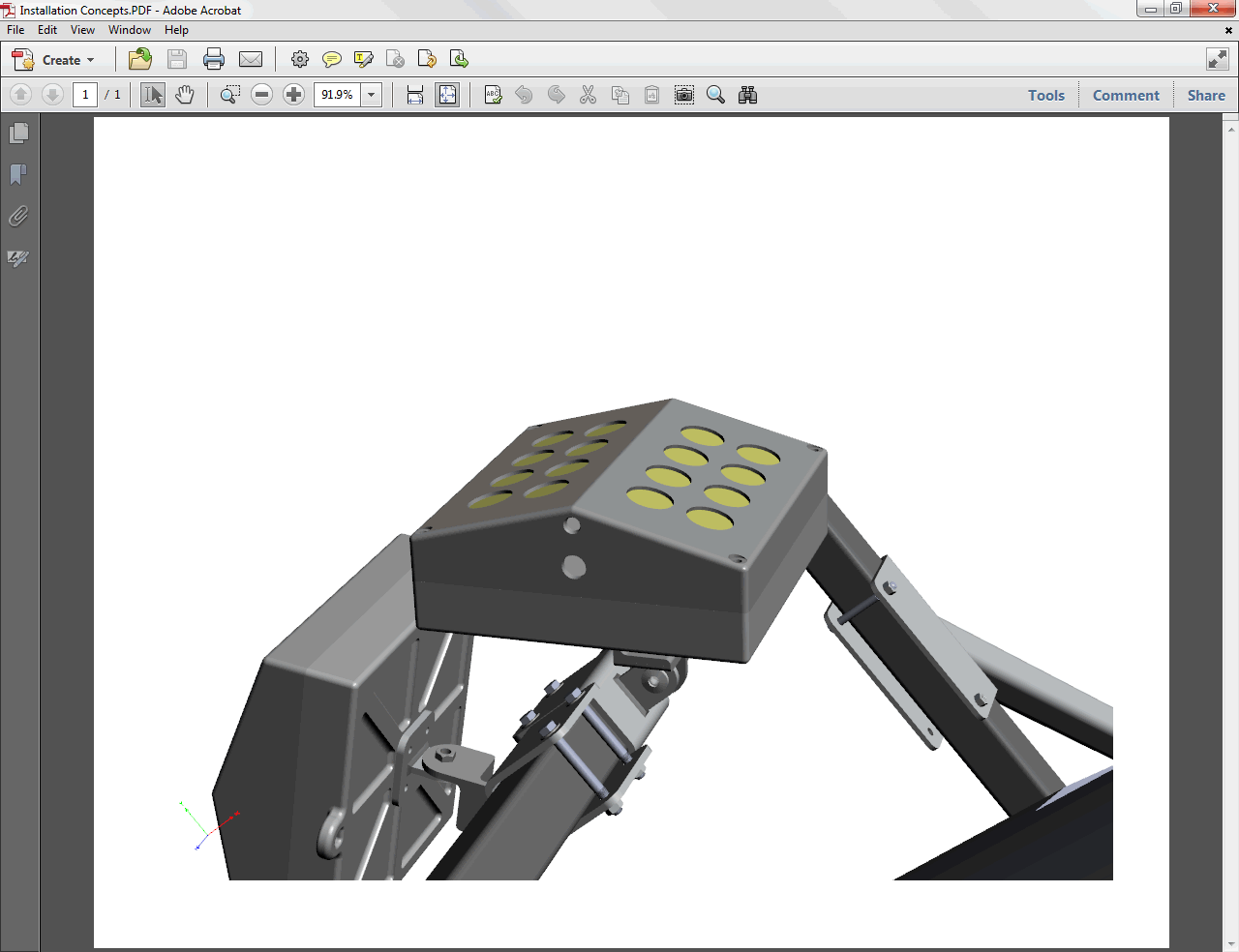

DEI developed a mechanical mounting system that utilized existing features on the nacelle of the wind turbine and secured 8 ultrasonic deterrents in place around the nacelle. DEI designed a regulating, current-limiting 300 VDC power supply to provide power to the amplifier circuits.

DEI manufactured bat deterrent systems and installed them on 10 wind turbines at a wind farm in Pennsylvania for field tests in 2009 and 2010. Deterrents were also shipped to the UK for testing in church buildings with unwanted bat populations. In 2013, DEI modified the deterrent system slightly for a field test at a macadamia nut farm in Hawaii. All of these tests produced encouraging results, suggesting that ultrasound is a promising method of reducing bat fatalities at wind-energy sites.

In 2014, DEI and BCI embarked on the design of a new generation of the ultrasonic bat deterrent system. Still in progress, this design effort will add alternate ultrasonic waveforms (white noise over adjustable ranges, single frequencies, pulsing modes, frequency sweeps), increased coverage through new mounting geometries, increased effective range through improved amplifier design, and remote control & monitoring.

Engineering Highlights:

- Power and amplified signal distribution for 128 ultrasonic transducers per wind turbine

- No nacelle modifications required for installation (except for cable entry in some cases)

- Remote control and monitoring (in development)

- Automatic recovery modes

- Microcontroller-based PCB design

- Firmware development