Step Into the Future

Deaton Engineering Designs Athletic Shoe Insert to Enhance Athletic and Rehabilitation Performance.

The Client: MedHab, LLC & RPM2

MedHab develops wearable technology – insoles that measure and monitor various metrics, giving medical care prescribers the ability to customize rehabilitation protocols to meet patients’ needs. Marketed as StepRite®, the device can measure body weight, force, gait, and flexibility in lower extremities using embedded sensors.

Utilizing the same technology, MedHab’s subsidiary RPM2 has developed a set of apps that, when paired with the athletic insoles, can measure an athlete’s bilateral equivalence, weight distribution and range of motion. Athletes whose legs are bilaterally in sync are faster, stronger, and perform better at a higher level.

RPM2 is an official Training Footbed Partner for USA Triathlon. Founded in 2008 and based in Fort Worth, TX, MedHab is a privately held company.

The Challenge: Design a small footprint smart shoe insole system.

In 2010, MedHab approached Deaton Engineering (DEI) to develop a proof of concept system in order to verify the feasibility of such a rehabilitation device. The main challenge was implementing all the necessary sensors and communication devices into a package small enough not to hinder a patient or athlete’s performance during daily use. The athletic insole system needed to withstand the wear and tear present inside athletes’ and patients’ shoes, while providing a reliable Bluetooth connection to a nearby device in order to sample data at up to 100Hz from a set of force sensors, a 3-axis accelerometer, a 3-axis gyroscope, and a 3-axis magnetometer.

The Solution: Miniaturized Smart Inserts & App

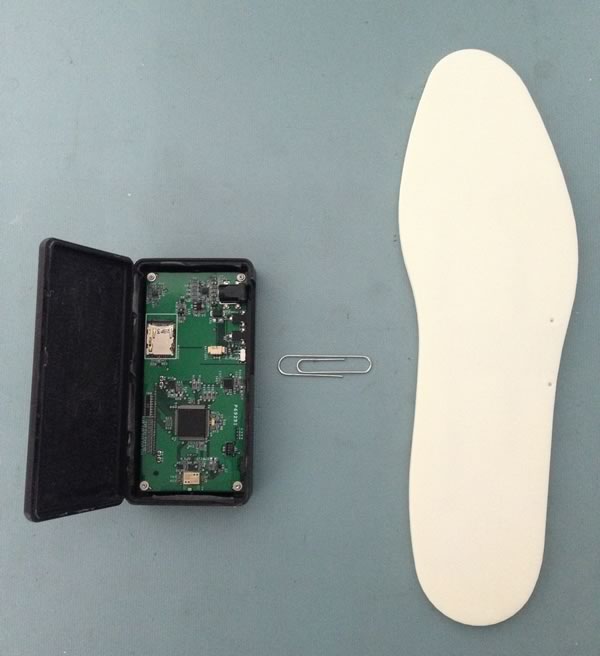

From the initial proof of concept (which was the size of a shoe box and powered off of 9V batteries, paired with passive insoles connected via ribbon cables) evolved a fully wireless device utilizing the latest in lithium polymer power technology and inductive charging miniaturized to fit inside a shoe insert.

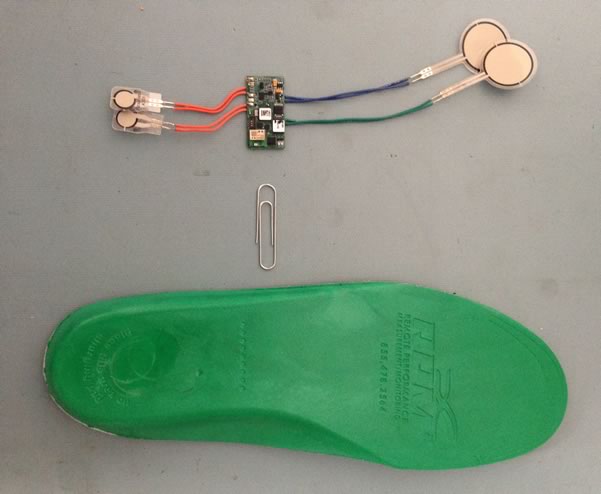

DEI developed a hardware system utilizing the latest in: low-power management, induction charging, Bluetooth communication, multi-sensor packaging, onboard memory, and BGA technology. Each insole housed a set of four force sensors connected to a miniaturized multi-layer PCB, which contained the 9-axis accelerometer/gyro/magnetometer, Bluetooth antenna and transceiver, induction and power management circuit, on-board non-volatile memory, and low-power microcontroller. All of this packaged into a board no bigger than a stick of gum.

DEI developed custom firmware that allowed the insoles to communicate wirelessly to mobile devices. DEI also developed the app backbone and APIs for Android and iOS devices, later used by RPM2 to create their own control apps.

Engineering Highlights:

- Fully encased miniaturized design able to fit into molded insole without external parts.

- Low-Power design utilizing lithium polymer rechargeable battery.

- Inductive charging capabilities for wireless battery charging.

- Bluetooth communication capabilities between the insoles and Android/iOS devices.

- 9-axis Accel/Gyro/Magnetometer & active force sensor integration.

- Microcontroller-based PCB design.

- Firmware and App (Android/iOS) development.