Conceptual. Compliant. Cool.

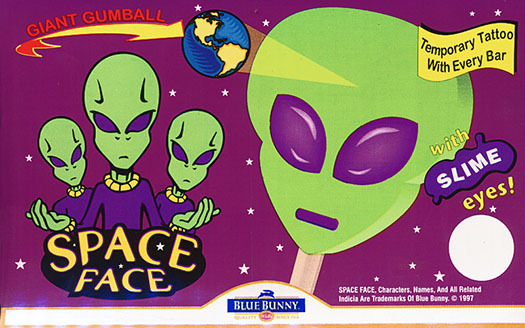

Deaton Engineering designs and integrates automated processing equipment for novelty ice cream production.

Ice Cream Novelty Products: Concept to Production

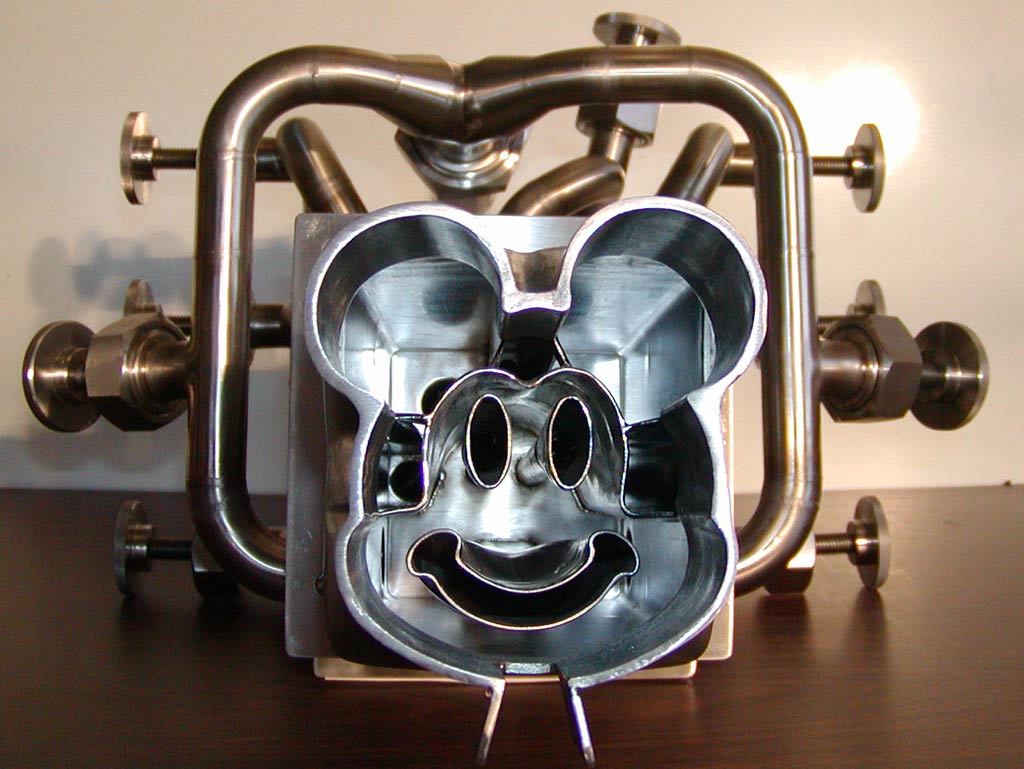

Deaton Engineering turns 2D drawings of novelty cartoon characters into 3D designs suitable for extrusion and production. Product design and size are based on customer’s equipment capacity.

- Stick slices

- Slices

- Sandwiches

- Cups

- Cones

- Bars

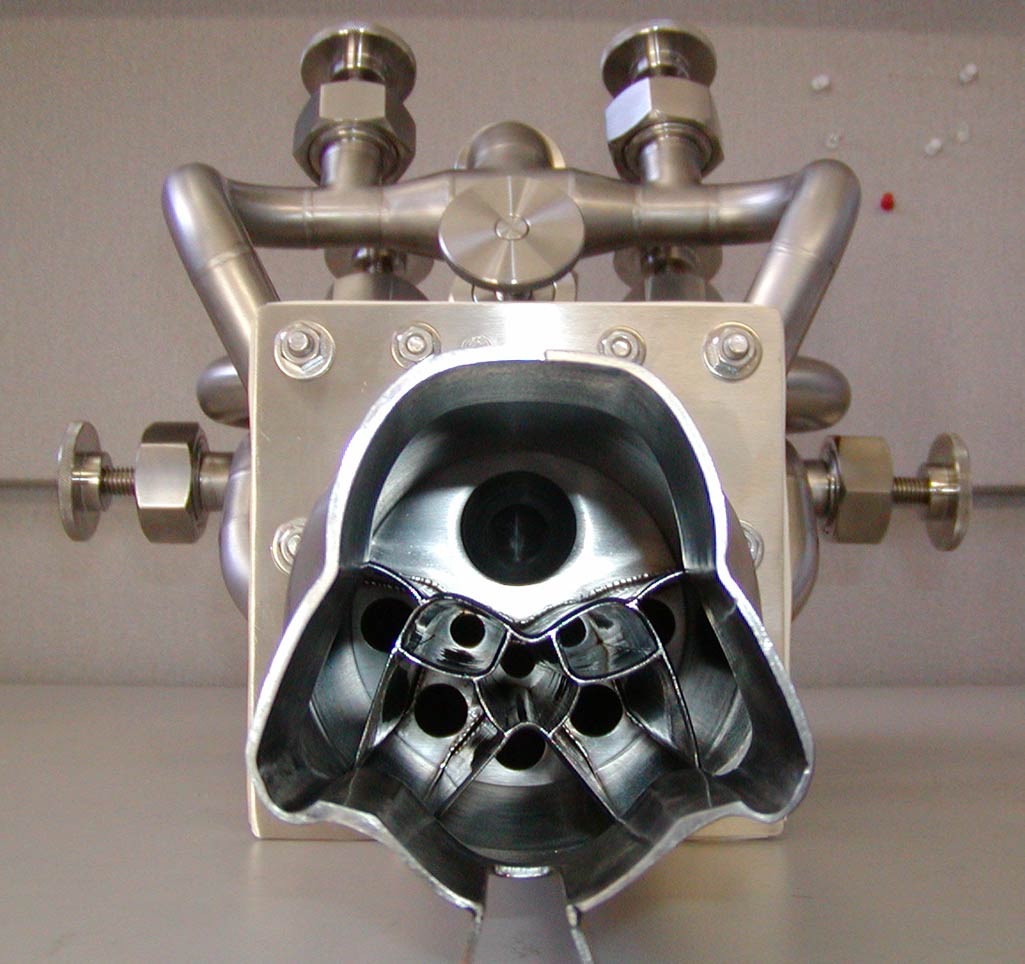

The Challenge: Design & Fabrication of Ice Cream and Water Ice Horizontal & Vertical Extruders and Nozzles

Deaton Engineering designs and fabricates ice cream and water ice horizontal and vertical extruders and nozzles. Our extruders are designed using parametric models to ensure they meet delivery and production requirements, and work the first time. The extruders can be designed for both new and existing product lines. Deaton Engineering understands sanitary design and manufacturing. DEI incorporates these principals into every extruder we design and fabricate.

The Solution: Custom extrusion equipment built for the demands of commercial production and compliance

Extruders & Nozzles - Horizontal & Vertical

- Single-flavor single-output

- Single-flavor multi-output

- Multi-flavor multi-output

- Complex multi-flavor

- Log products

Product Handling Equipment

- Stick gripper modifications and redesign

- Stickless pickup devices

- Cone pickup devices

Chocolate Coating & Enrobing

- Custom or product specific coating and/or enrober modifications

Other Components & Equipment

- Wafer Dispensers

- Nut & Candy Dispensers

- Conveyors

Machine Improvements:

- PLC programming & design

- Automation

- Clean, sanitary re-design

- Cooling & hardening tunnel modifications

- Liquid nitrogen applications

- Special application cutters

- Electronic drive retrofit

EPA Mandated Risk Management Plan and Program (RMP):

- RMP for ammonia refrigeration systems